What makes us special:

Test Machines

Long lifespan, consistent analysis reliability: that’s what Gläser test machines stand for. Learn more about our various test machines here!

Analytics

At Gläser, we offer the latest types of analyses in our in-house laboratories, tailored to your components and requirements.

Training

We are happy to share our long-standing expertise with you. Find out more about our training offerings and schedules here!

Process Review

Our experts from Gläser CleanTec support you throughout your entire process chain.

Laboratory Equipment

We provide everything from extraction machines to tweezers.

Why technical cleanliness?

Technical cleanliness is a key factor in production, increases the quality of products and improves cost-effectiveness by optimising processes.

Our services include component analyses, the development of individual specifications, the training of your employees and the optimisation of your processes.

Dirt particles, also known as residual dirt, can lead to malfunctions in important components. Residual dirt analysis is therefore an important part of quality assurance for customers in the automotive, medical technology, aerospace and electrical engineering sectors.

Using state-of-the-art testing machines for particle and residual dirt analysis, the cleanliness of your components is verified in accordance with the relevant specifications and standards. The aim is an efficient, cost-effective solution and support for optimising your processes in accordance with VDA 19.2 or VDA 19.1 / ISO 16232. Gläser CleanTec offers over 22 years of experience, 100,000 analyses carried out and an ISO 17025 accredited laboratory with an ISO class 7 clean room.

Technical Cleanliness – Q&A

Technical cleanliness is an important aspect in the manufacturing of components. It involves avoiding or removing contaminants such as dust, fibers, oils, or metal shavings. To ensure that components meet the requirements for technical cleanliness, various testing methods are used. This includes, for example, particle analysis, also known as residual dirt analysis.These procedures allow for the detection and quantification of contaminants.

One of the main reasons for technical cleanliness is to ensure the functionality of components and systems. By removing contaminants such as dust, dirt, or metal particles, it is ensured that the components function smoothly and are not damaged by impurities. Furthermore, technical cleanliness can also help extend the lifespan of components and systems by protecting them from corrosion and other types of damage. Another important reason for technical cleanliness is safety. Especially in the automotive and aerospace industries, it is crucial that components are free of contaminants to ensure they function reliably and safely. By adhering to standards for technical cleanliness, manufacturers can ensure their products meet the highest safety standards.

The answer to this question depends on various factors. If you are in the automotive or aerospace industry or manufacture other products where technical cleanliness is crucial, having your own test laboratory can be beneficial. In this case, you can ensure that your products meet the required standards and do not contain contaminants that could cause problems. However, setting up and maintaining your own test laboratory can be very costly. It requires specialized equipment and trained personnel to conduct the tests and interpret the results. In many cases, it may be more practical to collaborate with an external laboratory specializing in technical cleanliness testing. It is important to carefully assess whether your own test laboratory is suitable for your needs or if working with an external laboratory is the better option. A thorough cost-benefit analysis can help you make the right decision. If you decide to work with an external laboratory, make sure it is accredited and has the necessary experience and expertise to meet your specific requirements.

Our laboratories in Germany, China, Mexico and the USA are at your disposal. With our many years of experience and our in-house testing machines we can ensure that your components are sampled and the results analysed using state-of-the-art technology. We offer you comprehensive analysis and advice to detect possible contamination and recommend suitable measures to improve cleanliness.

Contact us for more information and let’s work together to improve technical cleanliness.Technical cleanliness plays a crucial role in the automotive industry, as even the smallest particles and contaminants can lead to serious problems. An example is the clogging of oil lines or the impairment of sensors, which can lead to malfunctions and even vehicle failure. To avoid these issues, the automotive industry places a special focus on technical cleanliness. This involves removing contaminants from all components and keeping them as clean as possible during the production process. To achieve this, special cleaning processes and technologies are used that achieve high cleaning effectiveness. Additionally, employees are trained and sensitized to ensure the cleanest possible working methods. These measures not only increase the quality and reliability of vehicles but also ensure the safety of passengers. Moreover, technical cleanliness contributes to environmental protection by reducing waste and pollutants through effective cleaning and avoiding contaminants. Overall, technical cleanliness in the automotive industry is an important factor that increases the quality and safety of vehicles and contributes to environmental protection. Therefore, a high value will continue to be placed on technical cleanliness in the future to meet the high requirements and expectations of customers.

The importance of technical cleanliness in medical technology is crucial for the safety of patients and medical staff. By adhering to specific cleanliness requirements, the risk of infections and other complications is reduced. Compliance with technical cleanliness is also an important factor in meeting regulations and standards in medical technology. Adhering to these regulations is necessary to obtain approval for medical devices and instruments and thus ensure their safety and effectiveness. Additionally, technical cleanliness impacts the lifespan of medical devices and instruments. Overall, technical cleanliness is an indispensable part of medical technology and significantly contributes to the safety and effectiveness of medical treatments. Therefore, companies in the medical technology sector should ensure that they take all necessary measures to guarantee technical cleanliness and thus ensure the safety of patients and medical staff.

Technical cleanliness is a critical factor in aerospace engineering. The cleanliness of components and systems can have a direct impact on their performance and reliability. Contaminants such as dust, dirt, fibers, or particles can lead to malfunctions or even component failure. Technical cleanliness is especially important in aerospace technology. Here, components and systems must operate under extreme conditions such as vacuum, temperature fluctuations, and radiation. Contaminants can not only cause malfunctions but also deteriorate the quality of materials. To minimize these risks, there are strict guidelines and standards for technical cleanliness in aerospace engineering. These include cleaning processes, packaging regulations, and control measures.

Laboratories worldwide

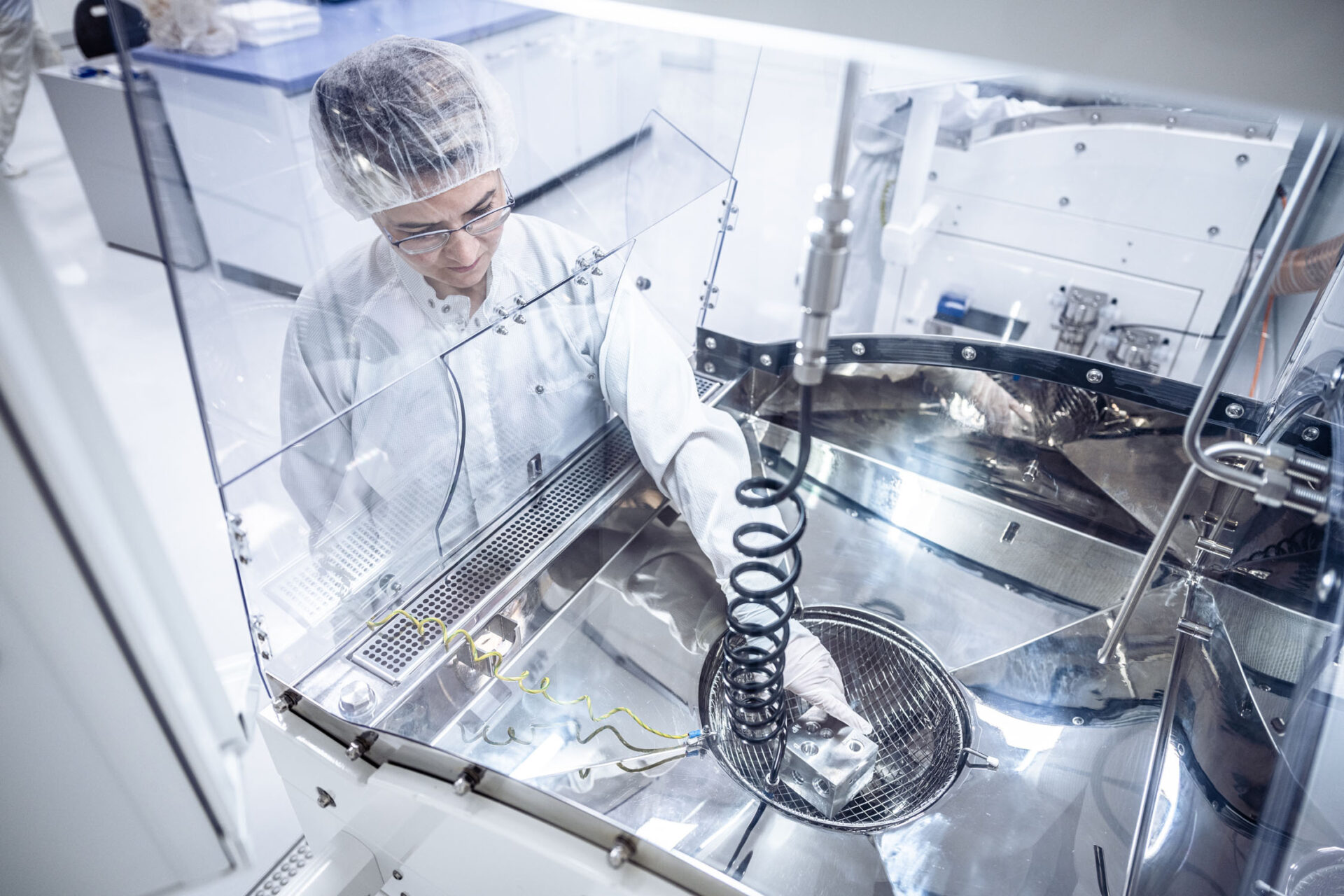

Particle extraction & analyses in the accredited test laboratory

Increase the quality of your products by optimising your production processes through the consistent application of technical cleanliness. GLÄSER CleanTec is at your side as a competent partner to fulfil these demanding requirements.

In our ISO 17025 accredited test laboratory, we offer comprehensive services for analysing your components. Our experienced and highly qualified laboratory team uses state-of-the-art laboratory equipment to analyse your components for particulate and chemical-film contamination.

Regardless of the size or nature of your components, we are able to respond flexibly to your individual requirements. Our expertise ranges from the extraction & analysis of particles from tiny components in the milligram range to the examination of large parts with a total weight of up to 350 kilograms. Thanks to our modern equipment and the in-depth expertise of our team, we can deliver precise and reliable results for every component, helping you to further optimise your production processes and ensure the quality of your products in the long term.

Rely on GLÄSER CleanTec to meet the high requirements for component cleanliness.

Contact

GLÄSER Sales Team

+49 7451 5392-0

sales@glaeser-group.com