Hydraulic control blocks tailored to your needs

You set the parameters and our team brings your wishes to life. Based on our extensive experience, we select valves independently of manufacturers or use brands according to your specifications. For CAD design, we use SolidWorks. With the help of a 3D model, the installation space can be easily checked before manufacturing.

Each control block manufactured by Gläser is functionally tested and adjusted to your requirements if necessary. Based on the available data and communication with you, we determine the type of control block that will be used in your application.

World market leaders trust and appreciate control blocks “Made by Gläser.”

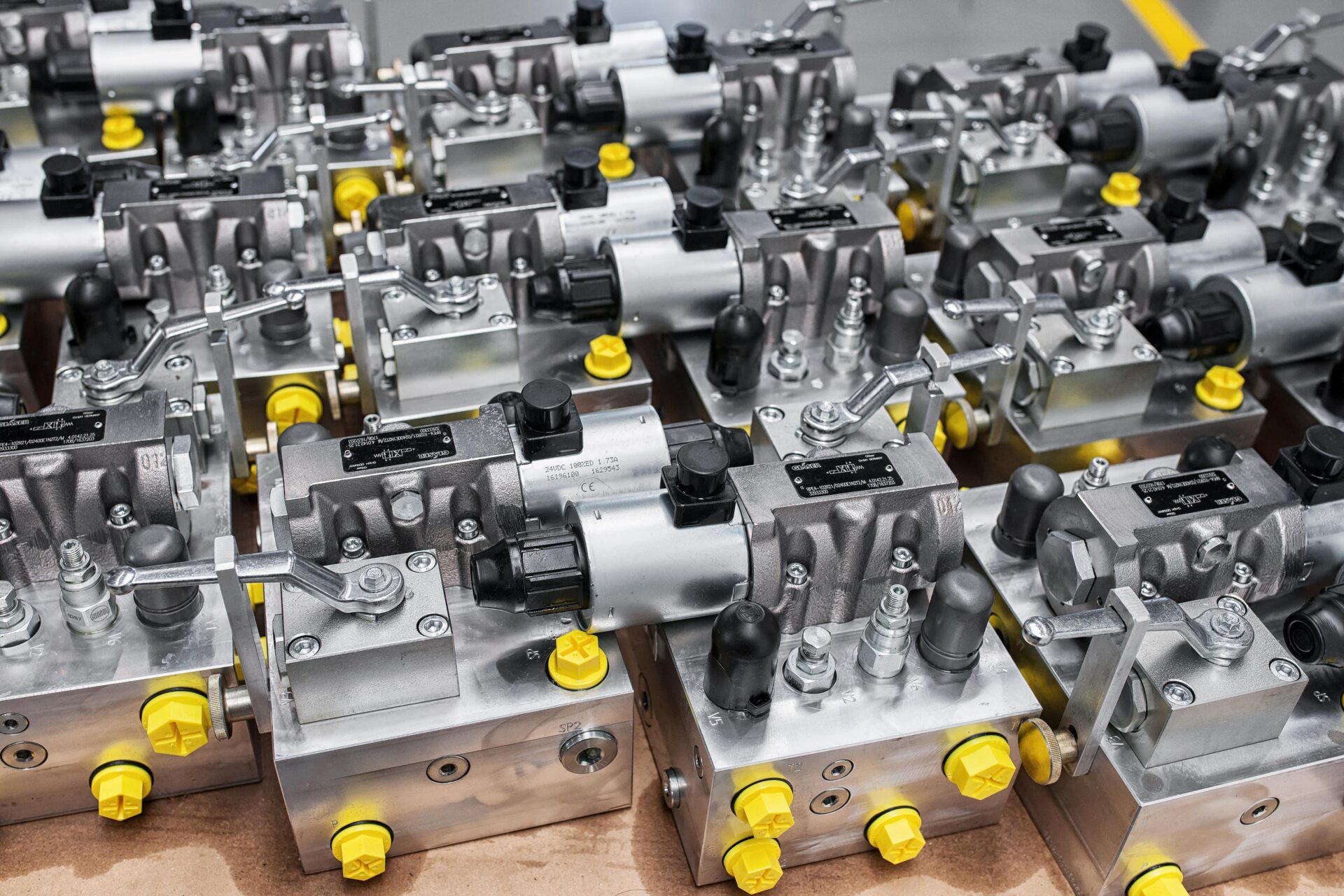

Large and Small Series Control Block Manufacturing

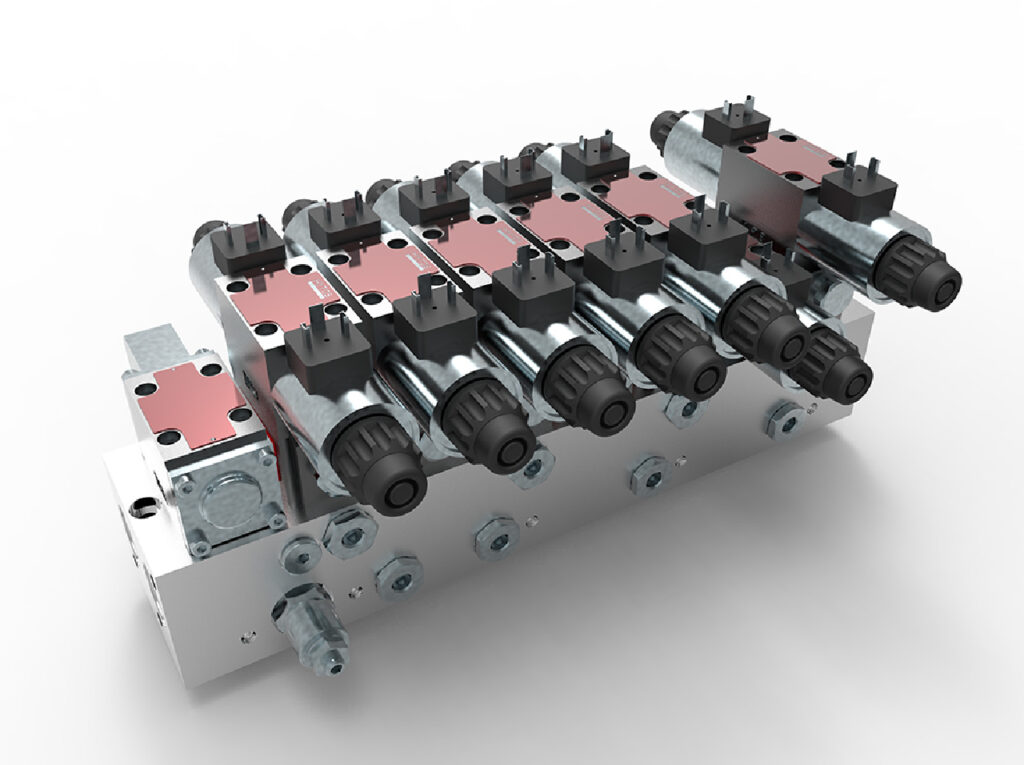

Monoblock Technology I:

For small to medium oil flows (up to approx. Q = 60 l/min).

With this design, the customer receives a control block that is particularly compact, weight-optimized, and adapted to installation conditions. Typically, screw-in valve cartridges or Cetop valves are used.

- The pipe connections are optimally positioned

- The valve components are service- and assembly-friendly

- Sealing surfaces and leakage risks are minimized

- Hose and pipe connections can be eliminated

- Costs are reduced

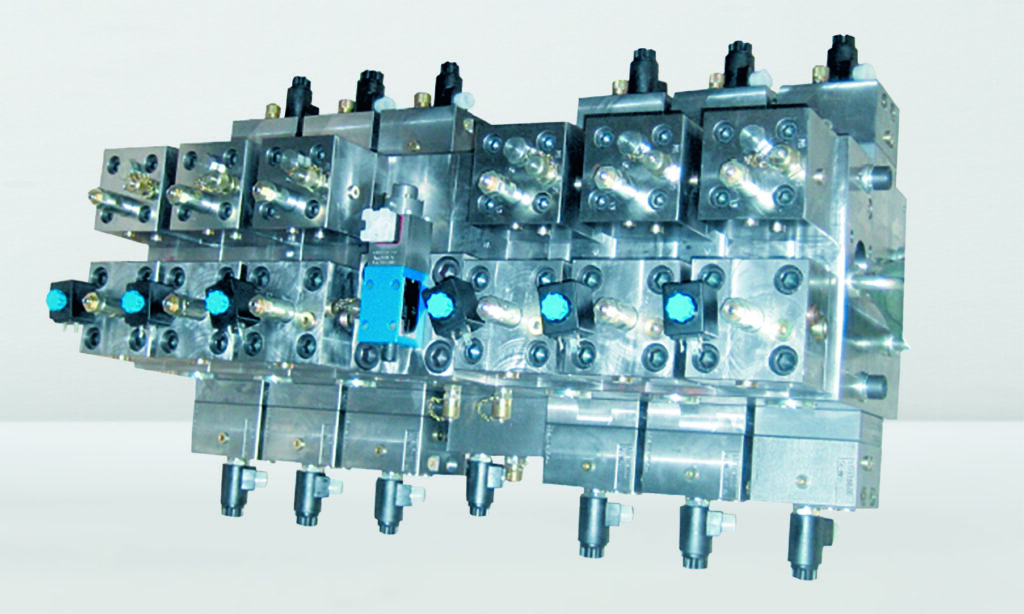

Monoblock Technology II:

For medium and large oil flows (up to approx. Q = 200 l/min).

In this design, 2-way installation valves, known as logic valves, are often used. Flange connections partially replace threaded connections. Screw-in valve cartridges or Cetop valves take over pre-control functions. The same design criteria apply here:

- The pipe connections are optimally positioned

- The valve components are service- and assembly-friendly

- Sealing surfaces and leakage risks are minimized

- Hose and pipe connections can be eliminated

- Costs are reduced

Connections with Cetop Valves:

This design also allows for control block solutions for specific cases. The customer thus receives a variable control block variant. Expansion options are available through a large range of intermediate plate valves. Cetop valves are used.

- The pipe connections are centrally located on one side of the block

- The valve components are stacked on top of each other

- Hose and pipe connections can be eliminated

- Costs are reduced

Modular Multi-Monoblock Technology III:

For large oil flows and multiple consumers (Q < 200 l/min).

In this design, monoblocks are made as flanged modules—multiplied. Functionally identical components can be supplied through central inlet or end modules. 2-way installation valves, known as logic valves, are used. Flange connections partially replace threaded connections. Screw-in valve cartridges or Cetop valves handle pre-control functions. The same design criteria apply here:

- Individual modules can be tested separately for functionality

- The pipe connections are optimally positioned

- The valve components are service- and assembly-friendly

Sandwich Control Blocks:

Especially for mobile applications: The proportional valve program PVG from Danfoss Power Solutions allows for nearly all customer requirements to be realized. From simple mechanical designs to electrically proportional valve systems with CAN-Bus control, various configurations can be achieved.

Solutions

Professional and Customer-Oriented

Whatever your current challenge may be, we will walk the path with you. You need to:

- Reduce piping effort?

- Minimize leakage points?

- Create space for additional options?

- Consolidate functionalities?

- Develop a new machine?

With Gläser, you have a partner who supports you from the beginning and is happy to visit your project on-site. With us, you have a partner that handles the entire process chain in-house. From consulting and design to mechanical manufacturing and expert assembly, and many testing options. Everything takes place at Gläser Hydraulics.

Nothing should stand in the way of a successful project realization! See for yourself our expertise.

Manufacturing Steps

State-of-the-Art Machinery for All Processing Steps

With our extensive and continuously updated machinery, we are able to respond quickly and professionally to the challenges of the hydraulic industry.

Sawing

Modern cutting machines, whether fully automatic or manual, ensure the desired result.

Drilling

CAD-based design drawings are implemented by our experts.

Milling

Fully automatic modern milling machines ensure the correct cut.

Material Selection

Whatever it is, we are experienced in it

In manufacturing, our focus is on processing aluminum alloys, hydraulic castings, and steel. For these materials, we have a comprehensive pool of mold tools for the cavities of renowned valve manufacturers.

Aluminum Alloy

Hydraulic Casting

Steel

Surface Protection

Gläser control blocks can be provided with different coatings upon request. Powerful companies in the region are our partners for your various requirements.

- Anodizing

- Chromating

- Galvanizing

- Painting

Reliable Components from Renowned Manufacturers

Gläser Hydraulics has maintained a close partnership with well-known manufacturers of high-quality hydraulic components for years. We supply a large part of the components from stock. Additionally, we offer comprehensive repair and service services. We also specify and configure products according to your individual requirements.

Orbital Motors

Danfoss orbital motors vary in size (displacement) from 8 cm³ to 800 cm³ per revolution. The speed is up to 2500 rpm for the smallest type and up to 600 rpm for the largest. Maximum torque ranges from 13 Nm to 2500 Nm (peak), and maximum power ranges from 2.0 kW to 64 kW.

If you haven’t found the right product or have questions about our product range, please contact us. We are happy to advise you.

Proportional Valves

Danfoss proportional valves are hydraulic load-sensing valves with maximum flexibility. From a simple load-sensing directional valve to an advanced, electrically controlled load-independent proportional valve. The modular design of the PVG allows for the specification of a valve group to precisely meet the respective requirements.

Joystick Program

Danfoss remote control levers are ideal for precisely and sensitively controlling your machines and systems. From our extensive product range, you will find the most suitable control element for your needs.

Steering Systems

Danfoss steering components are used in a wide range of vehicles and work machines. Wherever large steering forces need to be controlled and high safety and comfort are required, fully hydraulic steering components are used.