As an experienced machine builder, Gläser manufactures state-of-the-art test machines for performing residue analyses according to VDA 19.1 and ISO 16232 — now in their second generation.

The second generation offers not only technical and ergonomic optimizations but also significantly increased safety, with integrated explosion protection, meeting the recommendations of VDA 19.1, Chapter 11.2: Occupational Safety and Environment.

Which extraction system is the most suitable for you depends primarily on the geometry of the components to be analysed. Our product range extends from the ACM series for small to medium-sized components to the RiuS series for very large components up to 350 kg. All machines are equipped with at least the extraction methods of spraying and rinsing, ideal for performing cleanliness tests according to VDA 19.1 or your internal specifications.

Extraction Methods

Wet extraction, the most commonly used extraction method, covers a large portion of the requirements for particle extraction from components.

Through:

- Rinsing

- Spraying

- Dissolving

- Ultrasound

Particles are reliably detached from components and rinsed onto the membrane.

The right machine is usually determined by the size of the component being tested. The extraction chamber must be large enough to accommodate the component and allow for convenient handling.

Click here for our testing machines:

Dry extraction enables non-destructive sampling of air-carrying or electronic components and the gentle separation of particles from the component using filtered air without damaging it.

In this process, the hermetically sealed extraction chamber is first wetted with deionized water.

The component is placed inside and blown off with an air pressure nozzle.

The particles released from the component adhere to the previously wetted wall of the machine.

After sampling, the component is removed, the door is closed again, and the chamber is rinsed with deionized water mixed with a surfactant.

This ensures that the particles are reliably transferred to the filter membrane and can be analyzed.

Click here for our testing machines:

Drying of membranes

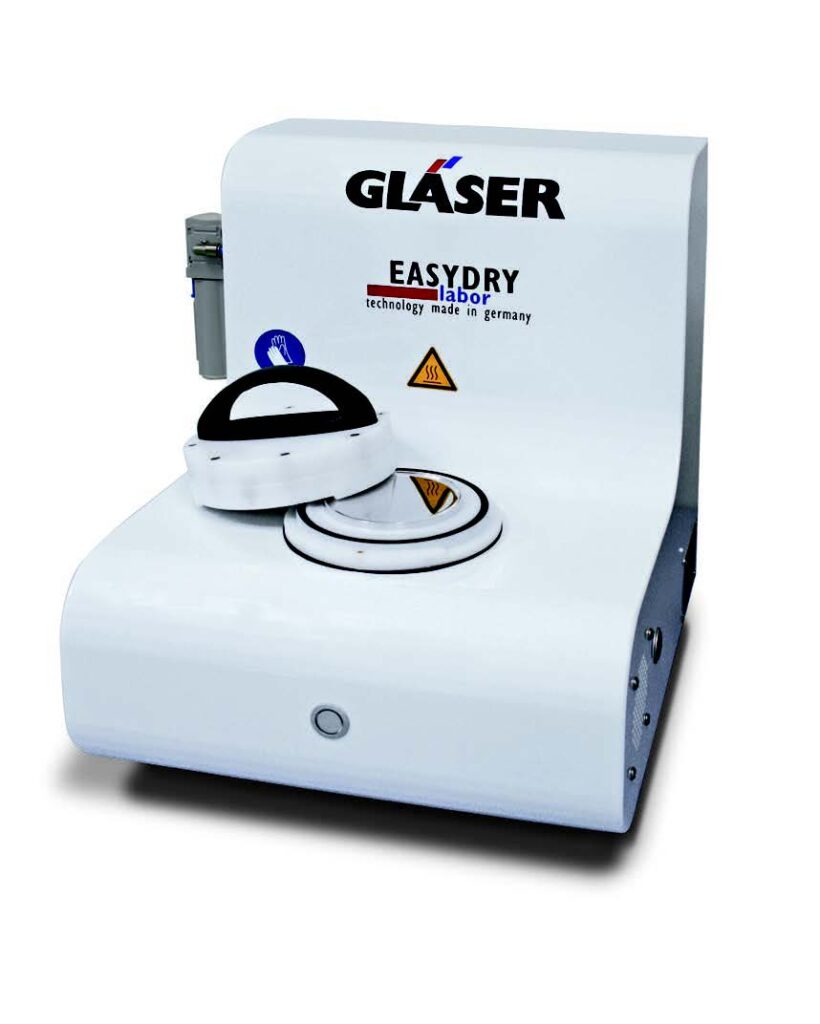

Easy Dry

With EasyDry, we offer you an innovative solution for membrane drying that impresses with its simple handling and high efficiency.

Thanks to the technology, you can be sure that your membranes are always optimally dried, which significantly reduces the drying time from up to 1.5 hours to 9 minutes and can therefore lead to less possible cross-contamination, i.e. impurities.

The EasyDry is not only user-friendly, but also time-saving, as it delivers fast and reliable results.

- Invest in the EasyDry and benefit from improved process reliability and quality in your laboratory.”

- Machine size (WxDxH) in mm 482 x 463 x 477

- Total weight 30 kg

- Machine type Membrane drying unit

- Membrane drying time approx. 7-9 minutes

What Makes Our Machines Special

Most of our machines feature:

- Extraction chamber in clean room class ISO 5 by supplying filtered air via the ceiling

- Extraction bar: Extraction of up to 90% of generated aerosols (when connected to existing ventilation by the customer)

- All our systems include:

- 12” Basic Touchpanel with intuitive software

- Liftable and swiveling membrane holder with three individual cascade rings; accommodates up to three membranes

- Comprehensive explosion protection concept

- Extraction basin made of polished stainless steel

- All wet extraction machines can optionally be operated with cold cleaner (HAKU) or deionized water

- Our machines can optionally be equipped with:

- Internal rinsing: Sampling of internal geometries and inner surfaces

- Large systems can optionally be equipped with:

- Manipulator for handling large and heavy components